A Comprehensive Guide to Warehouse Storage Systems and Industry Applications

Warehouse storage systems are essential components of any facility, whether it’s an e-commerce business or a food service supplier.

With a mixture of industrial shelving, pallet racking, mezzanines and other material-handling equipment, you can maximize storage space and get a handle on inventory organization—among other use-specific applications.

Understanding the many different types of storage systems is the key to designing efficient solutions for your business.

Let’s take a look at some common storage solutions and how different industries take advantage of material-handling equipment.

Static Storage Solutions

First, let’s explore static storage options.

These are your more common equipment choices, like shelving and selective pallet racking.

The key differentiator here is the fact that these storage systems don’t move. Most facilities will include static storage options in their warehouse layout design.

Selective and Other Static Racking

When you picture your average pallet rack, a selective racking system often comes to mind.

Selective rack allows operators to pick a single pallet without needing to move other stock out of the way.

While you’ll find quite a few variations of selective pallet racking on the market, most will leverage the same components:

- Upright frames

- Beams

- Decking (often wire decking)

Most systems utilize a keyhole and plug-style connector. The shape of this design will depend highly on the manufacturer, with the most popular being teardrop-style pallet racking.

Teardrop pallet rack is sturdy and durable, but if you’re looking for extra strength, consider structural pallet racking. Instead of roll-formed steel, structural racking uses stronger structural steel and a bolt-in configuration.

You can also find specialty racking options like drive-in racks for better forklift traffic logistics and cantilever racking for non-standard storage.

Shelving Options

If you’re looking to maximize industrial storage space, shelving is probably part of the solution.

You’ll find several different kinds of industrial shelving available:

- Backroom shelving

- Bulk rack shelving

- Rivet shelving

These are just a few common shelving types. You’ll most likely utilize all kinds of solutions to help meet your exact needs.

When shopping for shelving, always take into account what you intend to store.

For instance, small parts storage environments would benefit from backroom shelving. For heavier depalletized stock, rivet-style shelving can be a good choice.

Additionally, before purchasing shelving, assess your storage needs and inventory turnover rates to choose the right system. Consider factors like adjustability, ease of assembly and compatibility with existing systems for better integration.

Dynamic Storage Solutions

Static shelving and pallet rack options aren’t the right solutions for every storage environment. If you want to master efficient warehouse operations, consider dynamic storage systems alongside static options.

These can help when it comes to high-density storage or specific storage management systems like first-in-first-out (FIFO), last-in-first-out (LIFO) and much more.

Types of Dynamic Pallet Racking and Other Storage Systems

When it comes to dynamic styles of pallet racking, you have quite a few options, each with its own distinct advantages:

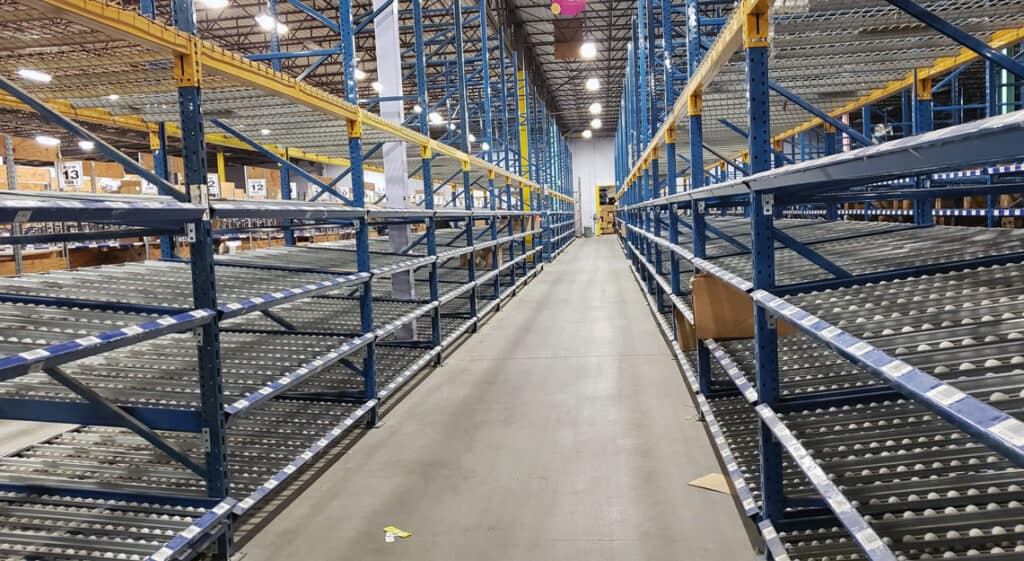

- Carton flow racking is perfect for managing depalletized loads packaged in cartons.

- Pallet flow racks leverage skate wheel rails to make FIFO-style picking easy.

- Pushback rack allows facilities to store pallets two to six deep in a single bay.

Depending on your particular storage needs, you might employ one or several solutions. Some facilities even require more complicated storage systems like pick modules that combine other equipment like conveyors with racking systems for optimized picking operations.

You can also find equipment like vertical lift modules in facilities that require intelligent storage for picking operations.

Common Industry Applications for Industrial Storage Systems

As you might imagine, plenty of industries leverage the power of commercial storage racks and shelving.

Maximizing storage space with the right equipment can have a direct impact on daily operations as well as productivity. Facilities need to carefully plan out their systems so they mesh with daily workload and inventory needs.

That’s why many businesses opt for professional layout design and installation of equipment.

Regardless of industry, equipment experts can help your team make the most out of your current storage space with the right tools.

To give you an idea of how these solutions might help, let’s take a look at a few industry-specific applications.

E-commerce

20% of all retail sales happen online—and the number is expected to grow.

For e-commerce warehouses to make the most out of operations, facilities need storage systems that can match the speed of business. That means leveraging both selective systems and dynamic solutions.

In truth, e-commerce facilities use all kinds of equipment:

- Storage racks and shelving

- Pick modules

- Automated storage and retrieval systems

- Conveyor systems

- Much more

Storing inventory is a big issue. Facilities need enough storage space to manage the ebb and flow of seasonal business while still keeping the warehouse floor safe for workers. Storage systems like pallet racking are essential to this goal.

Some facilities might leverage the storage power of a warehouse mezzanine as well—a perfect way to take advantage of underutilized vertical space.

On the Hunt for Affordable Warehouse Storage Systems?

Explore our wide selection of system solutions at East Coast Storage Equipment.CONTACT US

General Warehousing

Many different businesses need to store inventory:

- Lumber yards

- Shipping and receiving facilities

- Automotive and tire shops

- Manufacturing

Each of these businesses may require different types of storage equipment. For instance, a lumber yard will most likely need cantilever racking to deal with long and awkward loads.

Another business may need long-term storage for palletized loads of products. In this case, selective systems or even a pushback rack solution would be the right choice.

Cold Storage Environments

Storing inventory in freezers or other cold storage environments presents unique challenges.

For food suppliers and manufacturers, chemical producers and medical facilities, the need for durable and reliable cold storage means sourcing equipment made from strong materials.

Structural steel is the preferred choice here.

But, material choice is only one factor facing cold storage management:

- Layout and design—workers will need to move products in these systems, so make sure you’re sourcing the right equipment to maximize cold storage space and productivity.

- Accommodate lift equipment—in these cold storage environments, space is limited. Always make sure equipment gives enough room for lift vehicle access.

- Airflow and light transfer—often, product will need constant access to free-flowing air. In this case, source the right decking choice, like wire decking.

Get the Right Equipment with East Coast Storage Equipment

When it comes to reliable warehouse storage systems, you now have the basic knowledge you need to shop with confidence.

If you’re on the hunt for a reliable equipment supplier, look no further than East Coast Storage Equipment. With decades of experience, our team can help you find the right equipment to outfit your facility at an attractive price point.

Ready to get started? Get in touch with our team today.

Great blog post! I appreciate the level of detail you’ve provided on each point, making it easy for readers to implement these strategies in their own businesses. we at Giraffe storage solution provide various products to manage Warehouse Storage Systems effectively, Visit us for more details at https://www.giraffestorage.com/