Bins and Containers: Tools for Better Organization

When it comes to warehouse management, the devil is often in the details.

As your warehouse grows and your inventory diversifies, maintaining a streamlined, efficient operation becomes more difficult. A disorganized workspace can lead to lost productivity, increased errors and, in worst-case scenarios, even safety risks.

That’s exactly why you need to understand the power and benefits of a proper organization system — which often includes bins and containers.

Let’s explore bins, totes and containers and what they mean for your warehouse.

The Importance of Organization in a Warehouse

Organization is much more than just keeping things clean and tidy. In reality, organization is at the very heart of operational warehouse efficiency and productivity. When items are well organized, your team can find, access and move products more quickly and easily, speeding up virtually every task around your facility.

It’s also the key to reducing operational errors in order fulfillment, which, in turn, results in better customer service and a reduction of costs associated with returns and corrections. It’s that powerful.

Additionally, a well-organized warehouse is a safe warehouse. When you store things properly, you can:

- Keep aisles clear

- Decrease the risk of accidents and injuries

- Strengthen the safety of your team’s working conditions

With the Bureau of Labor Statistics reporting over 2,000,000 non-fatal injuries in 2021 alone, the impact of these changes can’t be understated.

Unfortunately, organization is not as simple as it sounds. Without proper organization tools, warehouses and other facilities can quickly become chaotic. Here are some common challenges:

- Wasted time: when workers spend too much time searching for items, they reduce overall productivity, leading to increased costs.

- Errors and misplacements: disorganization quickly leads to misplaced, incorrectly stocked and even lost inventory, leading to inaccurate inventory counts and delays.

- Damage to goods: items not stored correctly are at a higher risk of damage, leading to potential financial losses.

The key to staying organized is utilizing the right tools, such as bins and containers. When you implement organizational systems with equipment like bins and containers, you can mitigate many of these risks.

The Role of Bins, Totes and Containers in Organization

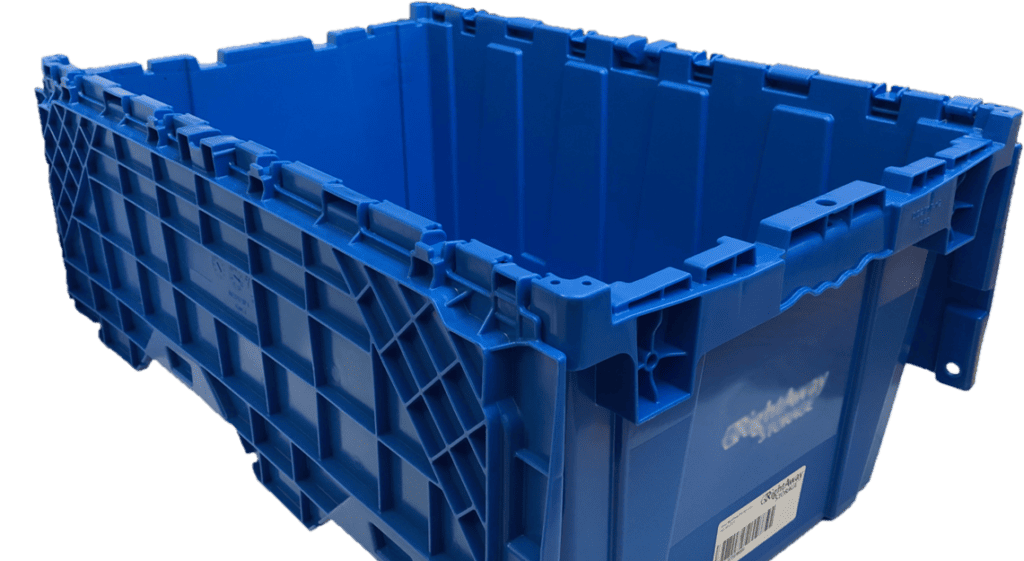

While bins, totes and containers may appear at first glance as simple storage equipment, with the right strategy, they can make all the difference in your facility. First, let’s start with bins.

Bins are particularly good for storing smaller items, with an open end for easy product retrieval, for, say, an automotive parts facility. When there’s a chance small parts will get all mixed up with other goods, bins tend to shine. By having a specific bin for each item, you can make sure every product is always in the right place.

When you have everything organized with bins, you can also maximize space — which is always at a premium in a busy warehouse.

Many bin designs are also stackable, allowing for optimized vertical space storage when not in use. For small warehouses working with limited square footage, this is essential. Next, let’s explore the value of containers and totes.

Like bins, containers and totes play a vital role in maintaining an organized warehouse.

What makes containers and totes a bit different than bins is their size and closed ends. Containers and totes tend to be larger, making them ideal for storing or transporting bigger and bulkier items.

Containers and totes can help streamline your daily processes in a few ways:

- You can group related items together, making it easier for workers to pick multiple items for an order.

- Containers and totes offer great protection for goods, limiting the risk of damage during storage or transportation.

- Like bins, containers and totes can also help to maximize space, particularly when they are designed to be stackable.

- Containers and totes can enhance warehouse safety, providing a secure way to store and move heavy or awkward items.

What makes a container different from a tote? Well, totes are usually collapsable — helping save even more space.

Of course, just purchasing bins, totes and containers will only get you so far. To get the most out of this type of equipment, you need to implement an organizational strategy that fits the needs and demands of your facility.

Ready to Maximize Your Warehouse’s Organization?

Discover our range of high-quality used bins, totes, containers and more at East Coast Storage Equipment.CONTACT US

Introduction to Color-Coded Bin Systems

First, what is a color-coded bin system? Simply put, it’s a method of organizing goods within your warehouse using bins of different colors. Simple, right?

To get this strategy right, you need each color to represent a certain type of item, category, zone or other type of unit. When you get it right, this visual system simplifies the process of identifying, locating and categorizing your inventory.

Benefits of Using a Color-Coded Bin Storage System

Using a color-coded bin storage system can provide some amazing benefits:

- Better item identification: with a color-coded system, team members can immediately recognize the type of items in storage based on the color of the bin.

- Inventory separation: different colored bins can distinguish between various types of goods, reducing the chances of mix-ups or contamination.

- Zone designation: color-coding can help define specific zones in your warehouse, making it easier to identify an item when it’s not in the correct zone.

- Reduced errors and improved efficiency: a color-coded bin system simplifies the process of selecting the correct item for a job, reducing errors and improving warehouse efficiency

With just the simple introduction of a color-coded bin system, you can expect some of the organizational benefits. But how can you quickly implement a system like this?

Implementing a Color-Coded Bin Storage System

So, how can you build a robust color-coded bin storage system for your facility? It all starts with deciding which colors to assign to which items, categories or zones.

After you’ve created an organization strategy, it’s time to purchase or label bins in these colors. Of course, this system is only worthwhile when your team understands it, so be sure to work through training sessions with staff to explain the new system.

It’s worth outlining the benefits of this type of system. Humans are curious creatures, so giving them the “why” around management’s decisions can help these ideas stick.

To help with these efforts, here are a few best practices:

- Post color-code reference charts to remind employees

- Group storage bins of the same color together

- Perform regular checks to ensure the system is working

- Adjust your storage strategy if needed

Get Organized with East Coast Storage Equipment

At East Coast Storage Equipment, we’re experts in material handling and storage equipment — including bins and containers.

We know that making the most out of your facility’s existing storage space can be a challenge; that’s why our team is ready to assist with everything from simple used equipment purchases to things like facility design and equipment installation.

Are you ready to get started maximizing your storage space? Connect with the team to learn more about your options.