Pallet Rack Bay Starters and Add-On Units: What’s the Difference?

You’re outfitting your warehouse and feeling overwhelmed with all the options. What’s the difference between bay starters and add-on units? What components should you order to build runs? And how can you determine how many of each unit you’ll need?

Designing and outfitting a warehouse requires a comprehensive understanding of the function and suitability of every shelf and rack. If you order the wrong thing, it could cost you money and time that would be better spent serving your customers.

That’s why we created this guide to ordering pallet racking for your warehouse. Keep reading to learn the difference between pallet rack starter and add-on bays.

What Are Pallet Rack Bay Starters?

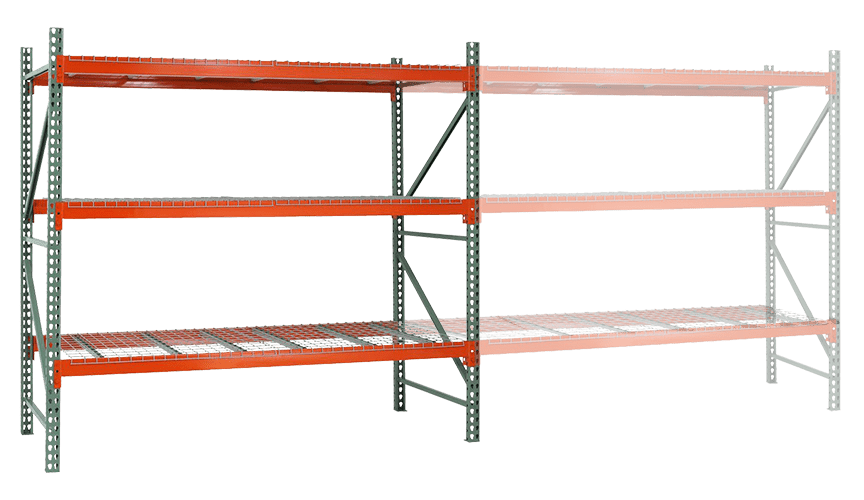

Pallet rack bay starters (or starter bay) are a complete unit consisting of two uprights on both sides of the beams. These sections can stand alone as single units or act as the beginning unit for a run of bays.

What Are Add-On Units?

Add-on units are incomplete sections of pallet racking. They are composed of one upright and a complete set of beams.

Because they only have one upright, add-ons cannot act as standalone units. They must be attached to the upright on either a starter unit or another add-on unit.

The Difference Between Starters and Add-Ons

The difference between pallet rack starter units and add-on units is in the uprights and the function they perform in a run of bays.

Both units have the same number of beams or wire decks, except starters will have two uprights, whereas add-ons will have one.

This means starter units can function independently from add-ons, but add-ons need either a starter or another add-on. The side of an add-on without an upright will need to be attached to the upright on another unit in order to be functional.

How to Build a Pallet Rack Run

In your warehouse, you likely want to create a series of continuous pallet rack runs composed of multiple bays. To do this, you must have at least one starter and one add-on unit. Each pallet rack run begins with a starter and is followed by add-on units. The number of add-on units will depend on the desired number of bays in the run.

For example, in a run with eight bays, the first one will be a starter, and the following seven will be add-ons.

How to Determine How Many Starters and Add-Ons You Need

Once you’ve determined which pallet rack types are right for your needs, the next step is calculating how many units you’ll need. These calculations will depend on your facility’s design.

Calculating the Number of Starters

Because starters are the only units that can stand alone, you will need one for every run and one for every standalone unit in your warehouse layout. This makes calculating the number of starters you need simple. Determine how many runs and standalone units you need — that’s the number of starters you should purchase.

Calculating the Number of Add-Ons

Add-ons are for continuous runs, and these calculations require more thought. Consult your layout to determine how many continuous runs you need to outfit. Then, record the number of bays each run will have. If your warehouse has 97 runs with 14 bays per run, you’ll need 13 add-ons for each run. Multiply 13 by 97 to arrive at the number of add-ons you’ll need.

When to Choose Pallet Racking

Pallet racks typically work best in large, busy warehouses. They are designed and built to be heavy-duty, and they provide proper storage for large, boxed or uniformly shaped inventory. If your warehouse uses forklifts or other heavy machinery to transport inventory, this type of racking may be best suited for your needs.

Looking for Personalized Storage Solutions?

We’ve got you covered. At East Coast Storage Equipment, we provide customized equipment solutions that maximize space and efficiency in your warehouse. CONTACT US

Other Storage Solutions with Starter and Add-On Units

This basic structure also applies to other shelving and storage solutions for warehouses. If you have cantilever, boltless or warehouse shelving runs in your layout, they will all be composed of starter and add-on units and will require the same calculations and planning.

Things to Consider When Designing Your Warehouse

Designing and engineering a warehouse that maximizes workflow and efficiency requires complex planning, an in-depth understanding of OSHA standards and comprehensive knowledge of different warehouse equipment. A holistic approach that considers multiple viewpoints and objectives will allow you to design a layout that works for your team.

When creating your design and layout, you’ll need to keep the following points in mind:

- The needs of your team

- Building requirements and codes

- Your measurements

- Potential obstructions

- Federal, state and local safety standards

Meeting OSHA standards is particularly important when designing your warehouse. Be sure to include aisle clearance between your pallet rack runs. The guidelines state 12 to 13 feet — wide enough to accommodate your forklift or other heavy machinery you may use in your warehouse.

Get the Right Combination of Pallet Rack Bay Starters and Add-On Units

Designing and engineering a warehouse with the right equipment can make a big difference in the productivity of your operation. A storage solutions designer must understand the difference between a wide variety of different units in order to select the right products for your unique needs.

If you’re looking for personalized storage solutions, we’ve got you covered. At East Coast Storage Equipment, we provide customized equipment plans that maximize space and efficiency in your warehouse. Contact us to see how we can help.