How to Anchor Pallet Racks

Depending on the type of pallet racking you have and the floor in your warehouse, your pallet racks might hold multiple tons of pallets. With that much weight on your racks, it’s going to be pretty important that they remain upright.

How do you keep pallet racks upright and in the right position? By anchoring them. In this post, we explore how to anchor pallet racks and the pallet rack anchoring standards you need to know.

For more information, keep reading. To get help finding or installing a pallet rack in your warehouse or distribution center, reach out to the experts at East Coast Storage Equipment.

Do Pallet Racks Have to Be Anchored?

If you’re looking for an excuse to skip this part of the pallet rack installation process, you won’t find it here. Pallet racks must be anchored to the floor. This is a workplace safety issue that both the Rack Manufacturers Institute (RMI) and Occupational Safety and Health Administration (OSHA) have weighed in on.

RMI Pallet Anchoring Guidelines

The RMI has long been in charge of setting safety standards for industrial racking and material handling, and the American National Standards Institute (ANSI) has vetted and approved the standards RMI has set for anchoring pallet racks. The standards are defined in this document, which is periodically updated and re-released.

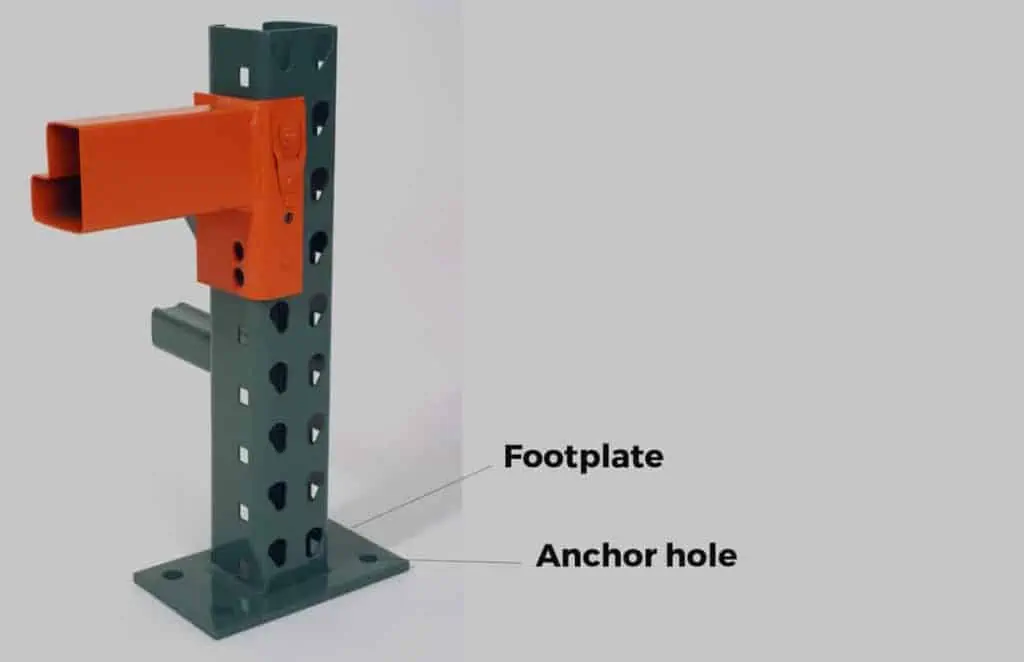

To make the very long story in that document short, you have to anchor all pallet rack columns to the floor. Each column has to have a baseplate or footplate, and those footplates have to be secured with an approved anchor bolt.

Why? It’s simple — the baseplates and anchors keep the rack from falling down. With properly anchored columns, a pallet rack can withstand forces like forklift collisions and even earthquakes without toppling.

Avoiding OSHA Citations for Improper Pallet Anchoring

If you need a better reason than worker safety to properly anchor your pallet racks, consider that this is one of the most common OSHA citations issued to warehouses. While OSHA doesn’t have regulations specific to how to anchor pallet racks, it does have a few general rules that it can point to when issuing citations for improper rack anchoring:

- The “Subpart N – Material Handling and Storage” chapter of the OSHA regulations, which states that, “Storage of material shall not create a hazard.”

- The published RMI rules we referenced above.

Keep in mind that your local building codes may also have some rules about how to anchor pallet racks. It’s best to take a look at those rules before you start anchoring.

Pallet Rack Anchoring Considerations

Pallet rack anchoring standards are not just a suggestion; they’re a requirement. Here is what you need to know before anchoring your pallet racks.

Floor Type: Concrete Is King

Concrete is really the only industrial flooring type that is strong enough to secure pallet racks that hold heavy loads. Linoleum, vinyl composition tile and epoxy probably won’t be sturdy enough. This is why the vast majority of industrial warehouses have concrete floors.

If you have a different type of flooring, speak with a material handling expert before installing any racks.

Do Your Level Best

The anchors that secure your pallet racks to the floor are strong. Once you get them in place, it’s going to take a lot to make the rack go anywhere. That means you have to be certain that the rack is level before you drive the anchors. Otherwise, your pallet rack may not perform well and may be improperly anchored.

Two Footplate Holes, One Anchor

The footplates on your pallet rack are the only connection point between the rack and the floor. Each standard footplate comes with two anchor holes in it. You might assume that means you need two anchors per footplate, but that’s not true.

In fact, footplates include two holes to give you some wiggle room. If, for example, you are anchoring a pallet rack and hit rebar under the surface of the concrete floor, you don’t have to move the entire rack and reconfigure your warehouse floor plan. Instead, you just switch to the other anchor hole.

In some cases, driving two anchors in one standard baseplate can stress the concrete between the two anchors and cause it to crack. Also, keep in mind that larger, non-standard footplates can include more than two anchor holes and require more than one anchor. It’s always best to consult the manufacturer’s recommendations and a material handling professional.

Installing Pallet Rack Anchors

Once you have planned out where your pallet racks will go, it’s time to install the anchors. There are several types of pallet racking anchors. Which type you use will depend on both your preference and the recommendations of the rack manufacturer.

If you’re not sure which type of anchor you should use, you can always reach out to the friendly and helpful team at East Coast Storage Equipment.

Selecting Pallet Rack Anchor Size

You can’t rely on personal preference when choosing the size of the pallet rack anchors you’ll use. The anchor’s size has to work with the baseplate anchor holes, size of your pallet rack and the concrete slab you will drill into.

For a standard baseplate, the most common anchor diameter is 1/2 inch, and the length can range from 2.75 to 6 inches. When choosing the length, consult manufacturer recommendations and keep the depth of the concrete slab in mind. Concrete slabs in industrial settings will usually be somewhere around 6 inches deep.

Wedge Anchors

Concrete wedge anchor bolts are meant for use in solid concrete, which makes them ideal for anchoring pallet racks. Here is a basic outline of how to install a concrete wedge anchor:

- Select a drill bit that is the exact same diameter as the anchor.

- Use a brush or compressed air to remove any debris from the hole.

- Place a washer and nut on the bolt before inserting the wedge anchor.

- Insert the wedge anchor into the newly drilled hole through the desired anchor hole in your footplate.

- Hammer the wedge anchor into the hole until it reaches the right depth.

- Tighten the nut.

Repeat this general process for each pallet rack baseplate.

Strike Anchors

Strike anchors are the other most commonly used pallet rack anchor. Like wedge anchors, these bolts are designed for applications in solid concrete.

The process for installing a strike anchor is similar to the process for installing a wedge anchor:

- Drill a hole with a drill bit that matches the strike anchor’s diameter.

- Clear debris from the hole with compressed air or a wire brush.

- Place the nut and washer onto the bolt.

- Thread the anchor through the baseplate hole and into the hole in the floor.

- Hammer the head of the set pin until the top of the pin is perfectly flush with the top of the anchor bolt.

Repeat this process for each footplate.

From Pallet Rack Installation to Selection, We’ve Got You Covered

We hope this guide has been helpful, but you don’t have to know how to anchor pallet racks in order to run your warehouse or distribution center. You can always call in the experts at East Coast Storage Equipment.We can handle everything from pallet rack selection and warehouse configuration to equipment installation, always keeping pallet rack anchoring standards in mind. If you need help finding a used pallet rack or installing one, don’t hesitate to reach out to us. Just call 888-294-5022 or contact us online.