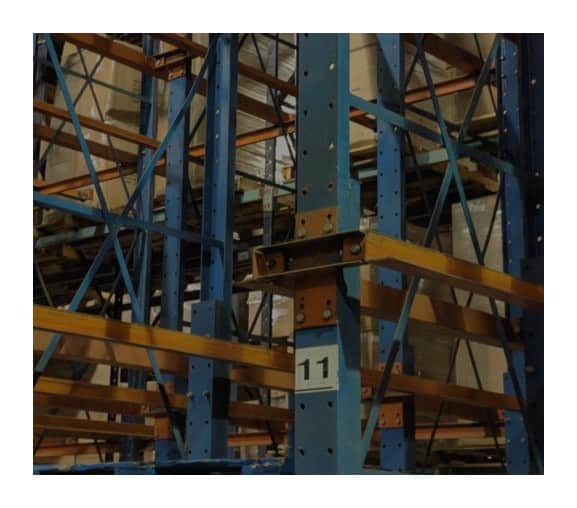

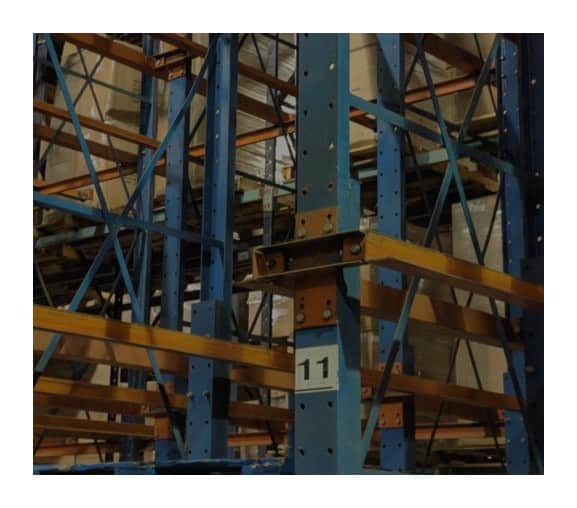

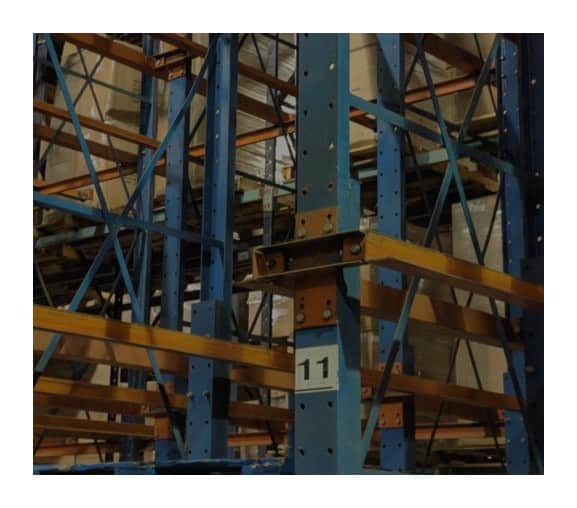

Drive-in rack is perfect if you need high-density storage for similar products. This type of rack uses a rail system on each side of the bay. There is no additional support under the middle of the pallet. As a result, pallets with heavy loads (or pallets in poor condition) may deflect causing potential problems when unloading.

Drive-in Rack Benefits

Drive-in racks offer economical storage. However, that economy assumes it doesn’t matter whether the first pallet is used first (versus the last). These racks offer storage capability up to 75% more in a small space, when compared to stacking on the floor or traditional selective racks.

Most drive-in rack systems have a storage depth capacity that varies from two to 10 pallets. Some manufacturers offer a double bay option. These racks use a slightly different rail system while allowing users to place two pallet loads side-by-side. The concept is designed to speed loading/unloading while increasing productivity. It also improves cubing of the facility.

Users considering this option must decide prior to installation on a single or double bay system. Racks cannot be retrofitted to change from single to double. Special forks are also required to use this rack option. Both options reduce the number of aisles needed when designing the warehouse. Many warehouse operations place drive-in racks against walls. You will find drive-in racks in warehouses storing having products in large volumes but with a limited number of SKUs.

Many manufacturers of food products (again, with a limited product line) choose drive-in racks. Cold storage/freezer warehouses also use this rack system because of its ability to effectively cube out small spaces. The racks typically are anchored to the floor. It gains additional support by attaching to the ceiling or with overhead bracing to provide stability.

Why Drive-In Racks May Not Be Right for You

While economical storage is a strength of drive-in racks, these systems also have challenges. Forklifts, as the name implies, drive into the rack, unlike traditional racks. This interaction increases the possibility of rack damage and safety concerns.

You may also experience a decrease in efficiency because the damage potential likely will slow loading and unloading times. Warehouses dealing with large volumes of multiple SKUs or use non-standard pallet sizes should not consider drive-in racks.

Drive-in rack offers significant advantages for warehouse operations. Improved storage on a small footprint. Large volumes in limited SKUs.