- Home

- Industries Served

- Food & Beverage

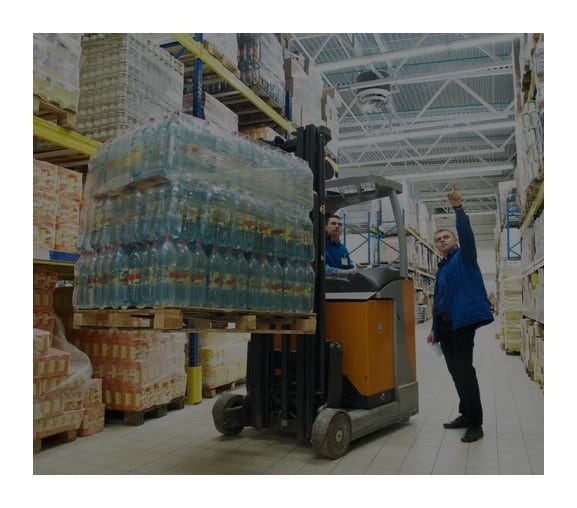

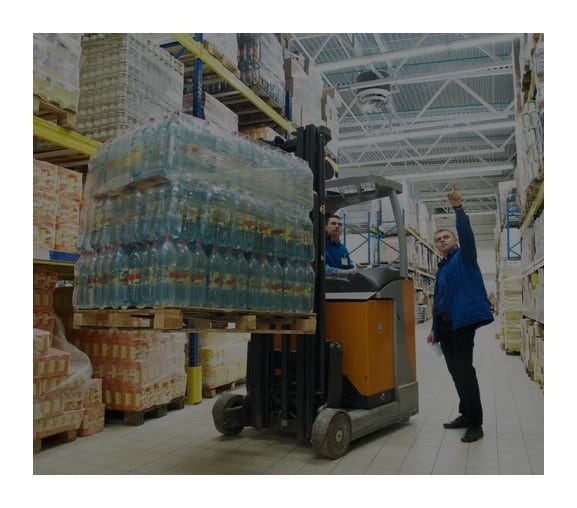

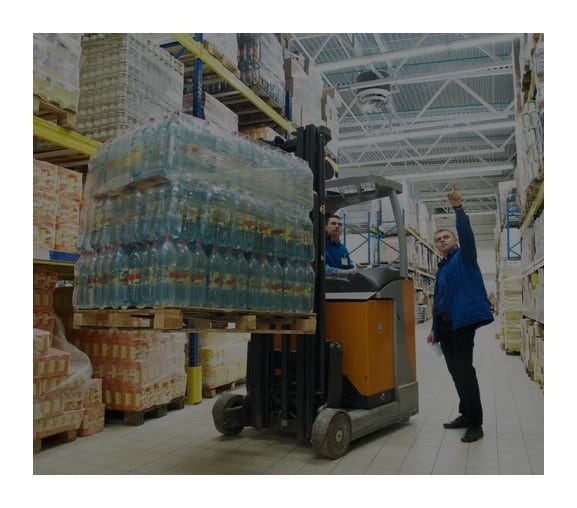

Food & Beverage

Food and beverage operations often need to maximize limited spaces to store what can seem like unlimited amounts of product.

Frozen storage, perishable inventory, expiration dates, temperature requirements, moisture, heat and light are all important elements of food and beverage bulk storage. Delivering palletized fresh, frozen and dry goods requires the footprint and the foresight to create a storage system that flows with the necessary speed for order fulfillment and product integrity. We can offer solutions that keep bulk goods flowing and fresh products safe for consumption.