Pallet Rack Planning Guide

With warehouses and distribution centers becoming increasingly important, having a highly functional, efficient warehouse layout has also increased in its importance. Whether you are purchasing a new space and need to optimize your pallet rack layout or you are reconfiguring your current space to maximize your floor space, having a pallet rack system plan in place can help streamline the design process and get your pallet racking up and running.

Pallet Rack System Planning

Our pallet racking tips and guidelines can assist you with creating the best design plan and process for your pallet rack system needs.

Pallet Rack Project Timeline

A well thought out project timeline can not only allow you to utilize your time well but also allows for you to properly assess all aspects and considerations when designing a pallet rack system.

While every project will have a different timeline, the pallet racking process follows this general timeline:

| Process | Timeline |

|---|---|

| Storage Requirements. Evaluate the size, type, location of your pallet rack system | 1 to 2 weeks |

| Seismic Calculations and CAD Drawings. Both are primarily needed for building permits | 2 to 3 weeks |

| Permits. Depending on your city/state regulations, permits will be required for most pallet racking projects | 3 to 7 weeks |

| Pallet Rack Procurement. The timeframe for pallet rack procurement depends on manufacturer lead times, customization, and size/scope of the project Procurement is largely dependent upon if you are purchasing a used pallet rack or if you are having a new pallet rack manufactured. New pallet racks have quicker ship times | 1 to 2 weeks |

| Installation. Installation depends on the size/scope of the project | 1 week to 1 month |

| Inspection/Approvals. Largely dependent on inspector availability and schedule | 1 day to 5 days |

Pallet Rack System Basics

Understanding pallet rack system basics can set you up for success and lead to long-term success with your pallet rack design.

Some basic pallet rack principles include:

- Load Capacity. Average pallet load and maximum pallet loads should be considered when designing your pallet rack system. Additional pallet rack capacity information can be found here and here.

- Pallet Rack Material. The type of rack steel used should be considered when discussing the load capacities required for support. Typical types include hot-rolled or roll-formed steel. Roll-formed beams are common and can be assembled with boltless beam connectors, offering a quicker installation than structural beams.

- Facility Features. Includes production zones and temperature. Floor space, ceiling height, and columns need to be considered when designing your pallet rack system. Your floors must be able to withstand the weight of your pallet rack system.

- Work Areas. Production work areas need to be considered when designing a pallet rack system. This is especially true for manufacturing companies or those with workspaces that pack and ship products.

- Material Handling Equipment. Equipment type, size, and aisle width are all factors to consider when designing a pallet rack system. The pallet racking must be able to accommodate the material handling equipment you use in your warehouse or distribution center.

- Product Type and Turnover. Your pallet rack system should factor in what types of products will be housed on the pallet rack shelves. The type of packaging system you use (such as first in, first out or last in, first out) as well as how often you need to access the pallets should be taken into consideration.

- Permits and Building Code Compliance. All pallet rack systems should be designed according to building codes and city permits. Failure to properly design a system that meets coding requirements could set back your timeline for pallet installation or require further changes to accommodate proper code compliance. Detailed information regarding pallet rack code compliance can be found here.

Pallet Rack Design Considerations

Utilizing floor space, vertical space, docking and shipping areas as well as allowing for inventory access are all components to consider when designing a pallet rack system. Other key factors to consider include pallet rack types, pallet rack styles, and pallet racking system configurations. Check out our blog post about pallet rack design considerations for more detailed information.

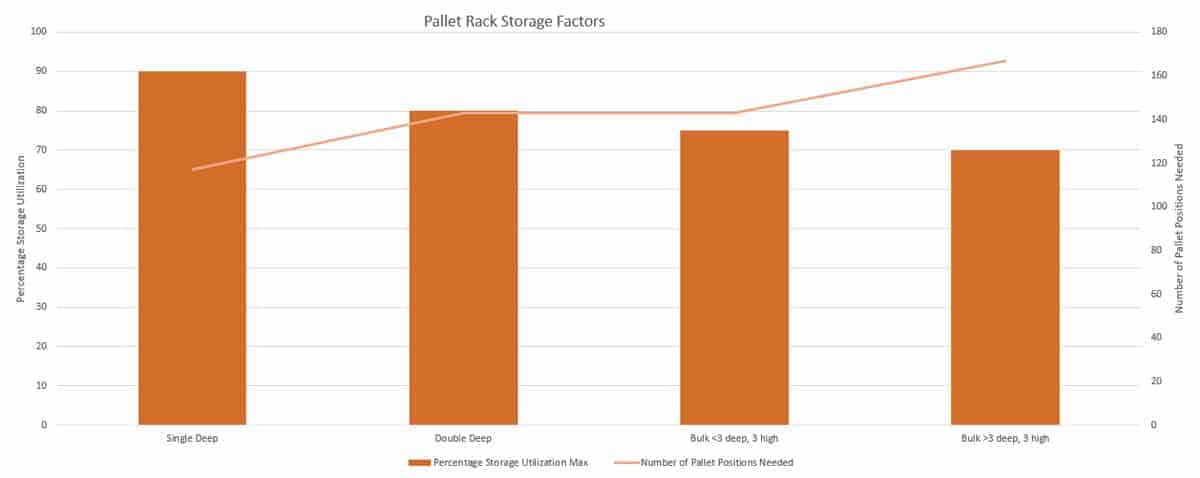

Pallet Rack Storage Factors

Effectively use your available space by maintaining storage utilization at 90% or less. Utilizing more available space can decrease productivity by limiting movement and functions. Storage utilization guidelines are as follows:

- Single Deep. 80%-90% storage utilization. 111-117 pallet positions needed per 100 pallets.

- Double Deep. 70%-80% storage utilization. 125-143 pallet positions needed per 100 pallets.

- Bulk < 3 deep, 3 high. 70%-75% storage utilization. 133-143 pallet positions needed per 100 pallets.

- Bulk > 3 deep, 3 high. 60%-70% storage utilization. 143-167 pallet positions needed per 100 pallets.

Data from this section derived from Steel King.

Selecting the Best Pallet Rack System for Your Needs

Pallet rack system considerations will largely depend on your specific warehouse or distribution center needs. In addition to factors like pallet rack type, style, and other planning aspects, another component of pallet rack system design includes establishing a budget. All the planning and system selection can be wasted if a budget is not properly considered and discussed with your pallet rack vendor. Talking to pallet rack system design experts can not only help you determine which type is best suited for your needs, but they can also help you keep within any budgetary parameters you may need to follow. The cheapest pallet rack system won’t always be the best and vice versa.

Additional Pallet Rack System Resources That Will Help

Please check out our other blog posts detailing more pallet rack information