How to Determine Cantilever Rack Capacity

If everything that goes in or out of your warehouse is a standard size that fits easily on a pallet, that’s great. But this simply isn’t the case for many warehouses and distribution centers.

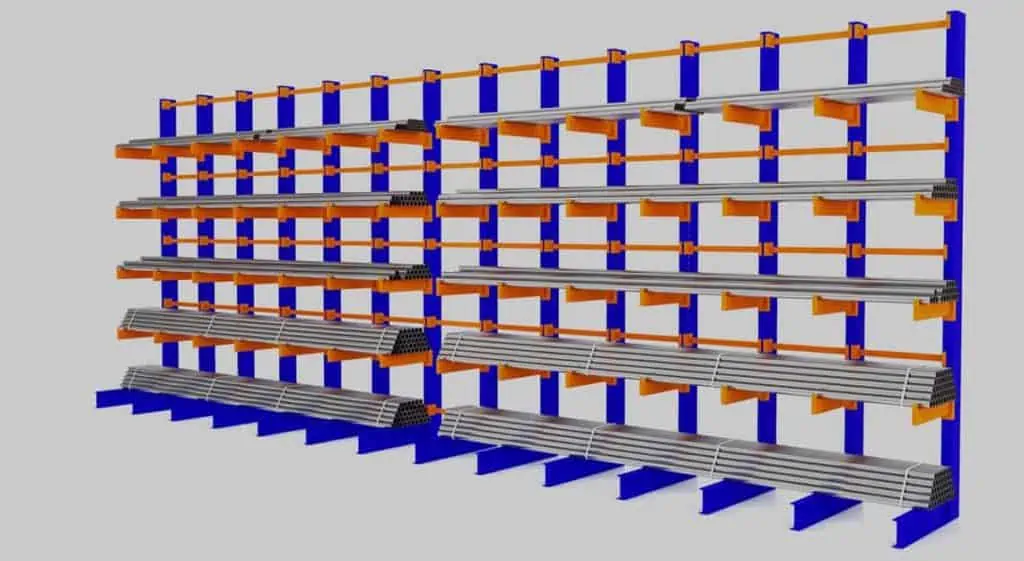

Cantilever racking has long been the go-to solution for the storage of long, irregularly shaped items, but when it comes to figuring how much these racks can actually hold, many warehouses are in the dark.

The team at East Coast Storage Equipment gets questions about cantilever racking weight capacity a lot. We’re happy to help. This quick, comprehensive guide will help you understand how to determine cantilever rack capacity. Read on to learn more.

Cantilever Rack Capacity: Getting It Right is Critical

Why does understanding cantilever racking load capacity matter in the first place? The answer is two-pronged.

First, determining capacity is a critical component of the overall safety of your warehouse. This may sound obvious, but it’s worth saying out loud: if you overload or improperly load your cantilever racking, you risk rack failure and falling objects. This can harm the products you’re storing, but the main concern here is potential harm to your employees.

The second concern is efficiency. If you are not utilizing your cantilever racking to the fullest extent possible, you may find yourself wasting both floor space and vertical space to accommodate additional racking. And unnecessarily spreading items out between multiple rack sections reduces picking and loading efficiency. All of these factors can have significant negative effects on your bottom line.

Factors That Affect Cantilever Rack Load Capacity

Some cantilever rack components come with load capacities printed on them by the manufacturer. This is a solid place to start, but the number from the manufacturer is an estimate. That’s because a wide array of factors can affect how much your cantilever racking can hold. Below, we cover some of the most important factors that can affect cantilever racking weight capacity.

Load Distribution

As a general rule, you need to distribute all loads on your cantilever racking as evenly as possible. An uneven load can reduce the overall capacity of the system by as much as 50% in some cases.

When you’re considering the distribution of a load, remember to account not only for the different levels of the racking, but also the other side of the racking if you’re using double-sided cantilever racks.

Arm Capacity

A typical 48X4 cantilever arm can support around 2,000 pounds. However, you can’t use the arm measurements to get an exact idea of the capacity of your overall system. For one thing, a 48X4 arm, 48X3 arm or really any size arm can be made from structural or roll-formed steel. Roll-formed steel tends to be lighter duty, meaning the capacity may be lower than the 2,000-pound benchmark. Meanwhile, structural steel may have a higher capacity.

Column Spacing

The more columns your cantilever system has, the stronger it is likely to be. Each column bears part of the load and provides another arm. When you’re storing long items like lumber or PVC pipe, you want to pay special attention to column spacing. If the columns are too far apart, you not only have a lower-capacity system, but you also face the risk of damage to the stored items near the center point between the columns they’re resting on.

Cantilever Rack Height

If you have a high ceiling in your warehouse or are planning to install your cantilever racking outdoors, you have a lot of vertical space available. Taking advantage of that vertical space can save on floor space and make your processes more efficient overall.

However, you have to consider height as you learn how to determine cantilever rack capacity. In most cases, a higher system will have a somewhat lower capacity per arm or row. So, while you’ll have more storage space on the racking, you might not have more total load capacity unless you reinforce or reconfigure the system.

Flooring

Cantilever racks sit on a base, and that base has to be anchored to the floor of your warehouse. Concrete is the gold standard for accommodating and anchoring heavy-duty warehouse racking, but even if you already have a concrete floor, you have to know a little bit more about it to understand cantilever racking weight capacity.

First, you need to consider the integrity of the slab. How thick is the concrete slab that makes up your warehouse floor? Is it damaged in any way? The integrity of the slab sets the tone for the overall capacity of the racking system.

You also need to make sure the floor where you’re going to place the cantilever rack is perfectly level. A nice, level floor is important for the stability of the rack, but it also helps the rack accommodate heavier loads. If your floor isn’t level, you need to square it up before installing your racking.

Searching for the Perfect Cantilever Rack System Your Application?

At East Coast Storage Equipment, we carry a wide selection of quality used cantilever rack systems for every application. Get in touch with us today.CONTACT US

Determining Weight Capacity for a Used Cantilever Rack

What if you purchase a used cantilever rack and have no idea how much it can hold? That’s a pretty common situation because used systems often don’t include a lot of the information that comes with new cantilever racking.

At East Coast Storage Equipment, we solve this problem for our customers in a couple of ways. First, we check the stamps on the racking components. Often, there will be a number we can use to look up the capacity information. In somewhat rare cases, the capacity of a cantilever arm will be stamped directly onto the arm, but we often have to look it up.

In cases where there is no stamp or additional information to pull, you can still get an idea of the rack’s capacity, but it might take an engineer’s touch. Our team will have an engineer spec out the system to determine its current capacity, and if you need the system to hold more, we’ll help you reconfigure it.

How to Increase Cantilever Rack Capacity

Cantilever racks can hold heavy, irregular loads, but what do you do when you need a system to hold more than it currently can? You have a couple of options. First, you can reconfigure or add to the system to increase its capacity. Adding arms and reducing the system’s height can improve capacity in some use cases.

Another go-to option for increasing cantilever rack capacity is adding cross bracing. These X-shaped steel braces connect the cantilever columns to increase strength across the system.

Cantilever Racking to Fit Any Need

Cantilever racks can handle heavy loads that come in diverse shapes and sizes. The versatility of this racking solution is one of the reasons it’s such a popular product at East Coast Storage Equipment. Our extensive cantilever racking inventory has a rack to fit the requirements of nearly any warehouse, and if we don’t have it, we’ll do our best to help you find it.

Once you’ve found the perfect racking solution, you can rely on our material handling experts to help you understand the cantilever rack load capacity. You don’t have to waste your time learning how to determine cantilever rack capacity — instead, we’ll do it for you and even help you install your new racking system. Interested? Give us a shout. Call (732) 451-1808 or contact East Coast Storage Equipment online today.

Please contact me to discuss an application for cantilever racks with 72″ long arms with 1,000 lb capacity. 4′ height spacing between arms. 3 arms total.

to be installed @ GapVax in Johnstown PA this summer