7 Best Practices to Make a Sustainable Warehouse

Warehouses are an important part of many businesses, but they can also be very taxing on the environment. Meanwhile, going green has become a trending initiative for many companies. From simple fulfillment services to local utility providers, it seems like everyone is trying to present a cleaner image.

That’s why it’s important to follow some best practices to make sure your warehouse is sustainable. However, many misconceptions surround what it means to have a green warehouse. So, what do you need to know if you’re looking to revamp your business and add some green practices to your everyday operations?

From changing up your waste management practices to switching to energy-efficient equipment, many actions can help you make a meaningful impact. Today, we’ll explore some simple practices you can implement to cut your business’s carbon footprint and keep your warehouse sustainable for years to come.

Reduce, Reuse, Recycle

The first aspect of your warehouse to make greener is your waste management practices. While cutting out waste completely is not usually an option, being smart about your waste stream can help you stay green and save money.

When it comes to waste management, always follow the three R’s:

- Reduce — Limit the amount of waste you produce.

- Reuse — Reuse materials whenever possible.

- Recycle — As a last resort, put items into the recycle bin.

Many businesses understand the last R but don’t do much about the first two. While recycling should be a part of your waste management stream, the less you put in the bins, the less impact you’ll have.

Moreover, you may want to invest in a baler. These devices are perfect for compacting waste of all kinds. The best part? You can sell some materials back for some extra revenue. Baling your waste also helps reduce the space you need to store all your garbage and recyclables.

This is especially the case when you pair a baler with the right storage system. Adding pallet racks to your waste management area can help your facility keep materials organized and ready for collection. As an extra bonus, buying used equipment, like used warehouse pallet racks, is a great way to reduce the impact of new equipment production.

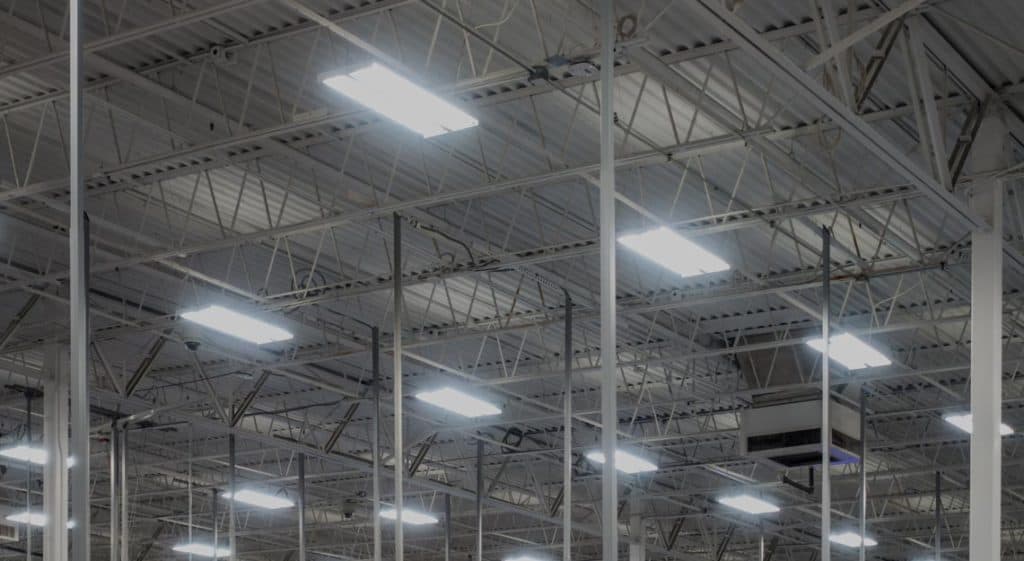

Use Energy-Efficient Lighting

Lighting can often seem like an afterthought. When you flip the switch, as long as the lights come on, everything is usually good to go. But did you know lighting has come a long way in the last decade? LED bulbs, for instance, have quickly become the dominant choice in lighting, and for many good reasons.

LED lighting is much more efficient and long-lasting compared to incandescent, fluorescent or CFL bulbs. How much so? Well, LED light bulbs use around 85% less energy than traditional incandescent bulbs and 50% less than fluorescent bulbs.

Moreover, LED bulbs produce less heat than other lighting systems. This can have a huge impact on your energy bills relative to cooling. This means LED bulbs produce less energy in the form of heat and more in the form of light — which is what you want if efficiency is on your mind.

The downside? It can be costly to revamp your entire warehouse with energy-efficient lighting. But once the upfront costs are out of the way, you pay less for lighting and less for cooling during the summer months. Additionally, LED bulbs last much longer than other bulbs, meaning you won’t need to replace them as often.

Use All of Your Space

Are you efficiently using all the space available in your warehouse? It may surprise you, but the footprint of your facility also impacts your overall carbon footprint. If you think about not only the necessary materials and impact on the local environment a larger facility has but the utility spend and costs associated with a larger location, you start to see the full picture of what that extra space will cost you.

To combat this issue, you can strategically utilize your current warehouse space. This means efficiently planning the location of all your storage equipment.

Planning ahead of time helps you maximize your current storage footprint. Moreover, material handling equipment can help organize and manage large storage spaces. Whether it’s long-term storage or a workspace, a detailed plan using the right equipment can quickly optimize your warehouse and reduce your overall impact on the environment.

All of this equipment helps you maximize your current space. Pallet racks and shelving can efficiently manage large storage spaces, and mezzanines open up your vertical space for all kinds of applications. Whether it’s storage or workspace, a detailed plan using equipment like mezzanines and shelving can quickly optimize your warehouse and reduce your overall impact on the environment.

Use More Sustainable Packaging and Packing Materials

This one should be a no-brainer. Packing and packaging materials that use plastics and other non-environmentally friendly materials are often the low-hanging fruit if you’re looking to go green.

With today’s trends in sustainable materials, it’s easy to source all kinds of sustainable packaging:

- Glass packaging

- Compostable packaging

- Paper and cardboard packaging

- Steel and aluminum packaging

- Wood and other miscellaneous materials

Moreover, if your business requires some sort of plastic packaging, you can opt for easily recyclable packaging. No matter what you choose, you’ll be adding value to your company and reducing your overall impact.

Energy-Efficient Equipment

If you’re currently using old warehouse equipment, you could be doing more harm than good. While we all want to get the most out of your equipment, at a certain point, you’ll need to make the switch to more efficient products. Even if you have a piece of equipment that is still running, you can find many reasons to make the switch — adding more green practices being one of them.

But it’s not only the environmental impact of old and inefficient equipment. It’s also about cost. If your equipment is in constant need of repairs or parts, it can mean you’re flushing money down the drain every time you have an issue. Faulty equipment can cost you revenue and productivity.

Moreover, manufacturers are designing equipment to not only be more efficient but also more environmentally friendly. This means fewer repairs and less energy wasted, which results in cheaper utility bills.

Ensure Your Warehouse Is Properly Insulated

Large warehouse spaces are a pain to heat and cool. That’s why proper insulation is the key to combating these issues. This is especially true for older buildings. But how do you know if it’s time to call an industrial insulation service?

Here are a few signs to watch out for:

- Drafty areas in your facility

- Higher-than-average energy bills

- Uneven temperature

- Thermostat can’t keep up

- Trouble with pests like rats and mice

- Visible damage to insulation

If you see any of these signs, it might be time to replace your existing insulation. A properly insulated building does much more than reducing energy costs. It can also:

Enhance workplace safety

Promote equipment longevity

Improve efficiency for certain industrial applications

Looking for Quality Used Storage Equipment?

Reducing your impact on the environment also means sustainably sourcing equipment. Learn how East Coast Storage Equipment can help. CONTACT US

Go Paperless Wherever Possible

Paper isn’t that bad for the environment, right? After all, it does come from a renewable source. What you might not know is the overall impact paper production has on the environment:

- You need 324 liters of water to make a single kilogram of paper.

- Almost half of the waste most businesses produce is paper.

- Paper accounts for around 25% of all landfill waste.

So, what can your business do to stay green while still keeping your team organized? Well, with today’s modern technology, you can easily switch areas of your business like billing to be completely paperless. Another tactic may be to revamp your picking process with scannable bar codes to help reduce the reliance on paper labels. You can also switch to portable printers to help reduce errors.

Here are a few other tips:

- Recycle all your paper waste (where applicable).

- Source 100% post-consumer waste products from suppliers.

- Scan documents instead of producing hard copies.

- Rely on email communication as often as you can.

Best of luck in your warehouse sustainability journey. The earth and your customers will thank you.